Turning A Problem into A Solution

Today the sign and visual industry is focused on getting the job done quickly, cheaply and with minimal labour input. Whilst this may have some positive outcomes for the customer, Large format digital printing has resulted in a considerable increase in the trail of pollution left behind. From aluminium composite panel signs that cannot be viably recycled or easily reused by the sign printing industry through to laminate and vinyl products.

Modern day manufacturing processes has resulted in the signage industry as being a significant contributor to single use plastic waste. The negative impact this has on the natural environment can be avoided.

What makes Remade Signage Eco-Friendly?

Remade Signage has partnered with responsible signage companies and utilises materials that they are unable to use or no longer require that would otherwise typically be sent to landfill.

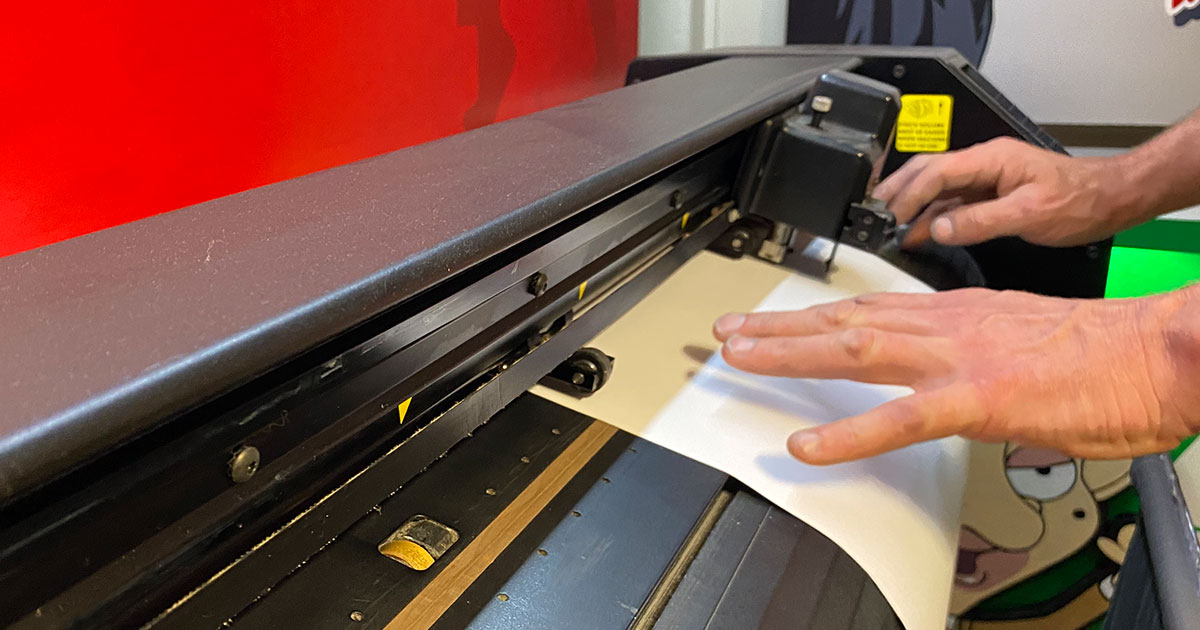

Repurposing unwanted laminate

One of the major waste products that are created by large format digital printers is laminate and self adhesive film. For example excess laminate material that comes off the end of a roll, film that has encountered a head strike during printing and even old or excess stock is typically sent to landfill by many sign making businesses.

In most cases this film is perfectly usable, it is not waste. At Remade Signage this film is used to create a mask/stencil to help create the first layer of a painted sign and as a guide to create additional layers and elements to the design.

Reusing Aluminium Composite Panels

Traditionally shop front and business signs used to be made using steel panels which were painted. When the sign had aged it could either be repainted or the steel could be recycled. However, this has now changed. The modern sign industry no longer uses steel panels or paint for making signs, instead it uses aluminium composite sheets and plastic stickers. Aluminium composite panels have a plastic core, with aluminium fused to the outer layers, meaning the sheets can not be viably recycled. As the modern signs start to age the stickers begin to deteriorate. It is very difficult to refurbish modern panel signs as new stickers will not adhere well to aged aluminium composite panels. Furthermore these sheets are manufactured overseas and are imported to Australia making them even more energy intensive.

By taking unwanted signs and left over material Remade Signage prevents these aluminium composite panels from going to landfill.

Used panels are first painted using a highly durable Urethane Acrylic water based paint, this covers any previous text/imagery on the panels, providing a clean base for a new sign.

The panels are then hand painted to the customers design specifications.

Low VOC Paints

With a continued focus on environmental impact, unlike traditional sign writers, Remade Signage does not use 100% enamel / solvent based paint. Instead approximately 70% of the overall volume of paint used to make the signs is a Low VOC water based paint called Eco Shield. These paints are manufactured in Australia by a family owned company named viponds. The use of these high quality, Australian made paints allows Remade Signage to offer a 10 year guarantee.

Why you should choose a Remade Sign

Recycled materials

you are preventing landfill

Longer lasting

10 year legible guarantee

UV Protection

100% painted graphics = No Peeling

Hand painted

With Australian made paint

Experienced

25+ years as a sign painter & installer

Aid reforestation

Support the Penahan Project